0 comments

Save

Share

Digitalization is getting more and more important for the value chain in merely any company. Especially in the production industry the trend goes towards finding ways of connecting analogue devices with the digital world. The more data a company can collect and evaluate regarding their manufacturing processes, the more quickly they can react in case some sort of malfunction occurs or optimize any aspect of the setup if necessary. It is key to collect as much information as possible while still maintaining all processes running. So, ideally the data collection happens in a minimal invasive fashion. Studies have shown that it takes only about 3-5 % of I/O-data for the company to be able to make smart decisions that ultimately increase the efficiency of the entire production process. Some manufacturers are worried that the collection and analysis of

their process data might be too time constraining and complicated. Plus,

some of them are concerned about the security of their highly

confidential company insider information (Cyber Security). Another

aspect to consider is whether all equipment used in the data collection

and evaluation is CE certified. Luckily, there are solutions out there

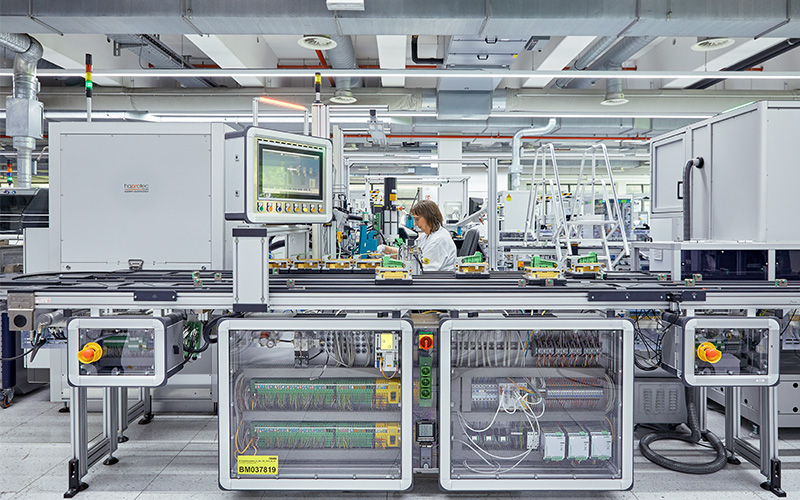

that address all these worries and concerns. The PLCnext Factory is a production site for electronics in Bad

Pyrmont, Germany. The site is specialized in manufacturing products for

automation, safety-applications, and network security technology. As

part of making the manufacturing processes more and more digital at this

facility, a PLCnext Control was installed into a Data Collection Box.

In form of Edge Computing this unit collects and analyzes data right at

the control unit. This helps making data-based decisions very quickly

and coherently, which ultimately help optimizing the production process.

The big advantage of edge computing is that the data collection and

analysis happen directly at the point of production so that there is no

time lost for transferring and/or evaluating the information at a remote

computing unit for example via a cloud. An efficient acquisition of data is essential to achieving complete

transparency in the production process to make production more

sustainable and efficient. The Data Collection Box from Phoenix Contact

was developed precisely for this purpose. It can be implemented to

collect extensive energy and process data without influencing or

disrupting ongoing operations. Since the data is collected, analyzed, and processed right there at

the point of origin, there is no risk of a security breach. Because the

data does not need to be transferred (let alone wirelessly) it is much

less likely that any confidential information will be stolen or

corrupted. Also, the data box offered by Phoenix Contact is fully CE

certified and thus perfectly suitable for any manufacturing facility.

Because the box can be installed externally at the control, there is not

even an additional auditing necessary. When digitalizing existing production facilities or machines, it may

become a challenge to include older analogue devices into the digital

setup. Fortunately, with PLCnext Technology retrofit installations of

already existing devices are not a problem. Thanks to the modular and

compact design, both greenfield and brownfield applications can be

easily implemented with the different versions of the box. The data that is being collected at the box or edge device can be

analyzed, evaluated, or visualized in multiple ways, depending on the

specific needs of the actual setting. There are countless options for

further processing the acquired data, for example by uploading it into

an external cloud server. The user forum at this PLCnext Community

website is an informal network of users and developers from around the

world, who are all working with PLCnext Technology. They offer great

insights and valuable advice on finding just the right apps and codes

for any distinct requirement or infrastructure. One of the advantages of

PLCnext Control is their compatibility with merely any software app and

code language available. Getting production sites ready for the era of digitalization is not

only an engineering but also a managerial matter. While manufacturing

facilities used to be designed for long-term usage and often entail

highly complex infrastructures, the trend now is towards more adaptable

and agile setups. It makes more and more sense to establish modular

production architectures that function independently with both its

various analogue devices but also software applications. The goal is to

ultimately have all processes running as smoothly and efficiently as

possible. Data acquisition and evaluation plays an integral part in

making the production processes even more efficient. Thanks to their

openness for all current codes and apps as well as their readiness to

retrofit existing devices, the PLCnext Technology Ecosystems are a smart

solution for moving production processes into the digital world.

A factory dedicated to making other factories more efficient

Including existing analogue devices into digital setups

Shifting production processes into the digital era